2020-12-16

Greater loading clearance and longer operating lif

RINGSPANN presents new 15° clamping discs with higher true running accuracies

Expanding the technical potential of the RINGSPANN clamping disc has always gotten RINGSPANN’s innovative juices flowing. Based on the functional principle of this flat tapered spring steel ring, the company regularly presents new clamping technology solutions, die die Bearbeitung zylindrischer Getriebeteile für den Automobil- und Maschinenbau sowie die Luftfahrt- und Fluidtechnik weiter voranbringen. In diesen Tagen ist es wieder soweit: Erstmals präsentiert das Unternehmen neue 15°-Spannscheiben für seine Flanschfutter und Flanschdorne der Spannscheiben-Bauform. Das Besondere daran sind ihre exzellenten Rundlauf-Genauigkeiten von nur 10 Mikrometer!

Bad Homburg, December 2020. – The LAFF series flange chucks and LBDF series flange mandrels from RINGSPANN rank among the precision clamping fixtures that have been setting the tone in metal-cutting machining for many years. Wherever cylindrical workpieces have to be centred and internally or externally clamped in the automotive industry, in aircraft technology or in the manufacture of pumps and gears, these chucks guarantee excellent results. The functional - and name-giving - heart of these flange chucks and mandrels are their RINGSPANN clamping discs (see info box I). They are combined into ring-shaped and pre-stressed packages between 4.0 and 20 mm wide, depending on the number of discs. Their size follows the clamping diameter required for machining the workpiece. This ranges up to 170 mm for chucks and 200 mm for mandrels.

More comfort when loading

A key quality feature with a decisive influence on the precision achievable during milling, turning, drilling, grinding or balancing is the true running accuracy of the clamping discs used in the LAFF flange chucks and LBDF flange mandrels. Until now, the standard setter has been clamping discs with a taper angle of 9°, because they alone achieved a true running accuracy of ≤ 10 µm. A few months ago, however, the RINGSPANN engineers set themselves the goal, as part of a medium-term development project, of developing further clamping discs with an improved true running accuracy, which would provide the user with two crucial advantages without compromising on accuracy: On the one hand, the aim was to enable significantly larger diameter changes so that a much more comfortable loading clearance is available; on the other hand, the clamping discs should have a considerably longer service life thanks to greater wear reserves.

"As a result of our development work, we can now offer suppliers and mechanical engineers two new series of clamping discs or bonded disc packs with taper angles of 15° whose true running accuracy is also ≤ 10 µm ¬- with an expanding rate that is about four times greater," reports Volker Schlautmann, head of the customer team for clamping fixtures / shaft-hub-connections at RINGSPANN. Up to that point, the 15° clamping discs had achieved true running accuracies of just ≤ 30 µm. The considerable improvement in the true running properties was made possible by the internal switch to a different production technique. A new production method is the key to this change, which now enables the 15° clamping discs to be precision-ground on both surfaces ¬- as has long been the standard with RINGSPANN’s 9° clamping discs.

Gentle clamping of sensitive workpieces

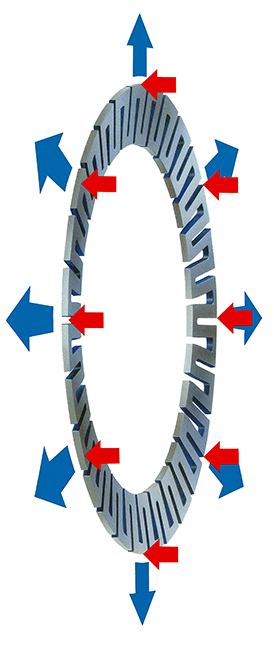

Equipped with the new true running-optimised 15° clamping discs, the new LHFF flange chucks and the new LIDF flange mandrels are now predestined for machining tasks with very high demands on machining accuracy. At the same time, they provide users with a high-precision solution for centring, aligning and clamping cylindrical workpieces whose inner and outer surfaces have already been pre-machined - in other words, components for which value creation is already well advanced! Thanks to the precisely circular expansion of the flat tapered clamping discs, the torque is always transmitted to the workpiece with an all-round uniform pressure force. "This homogeneous 360° clamping protects the surfaces of the component and makes our LHFF flange chucks and LIDF flange mandrels - especially because of the increased true running accuracy of their new 15° clamping discs – well suited for machining thin-walled, deformation-sensitive precision components", stresses customer team leader Volker Schlautmann. The permissible workpiece tolerance of these clamping tools ranges up to IT13, and for most sizes even up to IT14. ms

The RINGSPANN principle

The RINGSPANN clamping disc machine element is inextricably linked to the history of the company of the same name. It is an invention of the company founder Albrecht Maurer and can be found today as a mechanical system component in numerous clamping fixtures and couplings of the manufacturer. It is a flat-tapered ring made of special hardened spring steel, which features a characteristic slotting to lend it a unique elasticity. An axial actuating force causes a change in the taper angle and diameter at the same time. If its inner diameter is supported by a mandrel, the diameter increases; if the outer diameter is supported, it decreases.

Axial movement becomes radial force

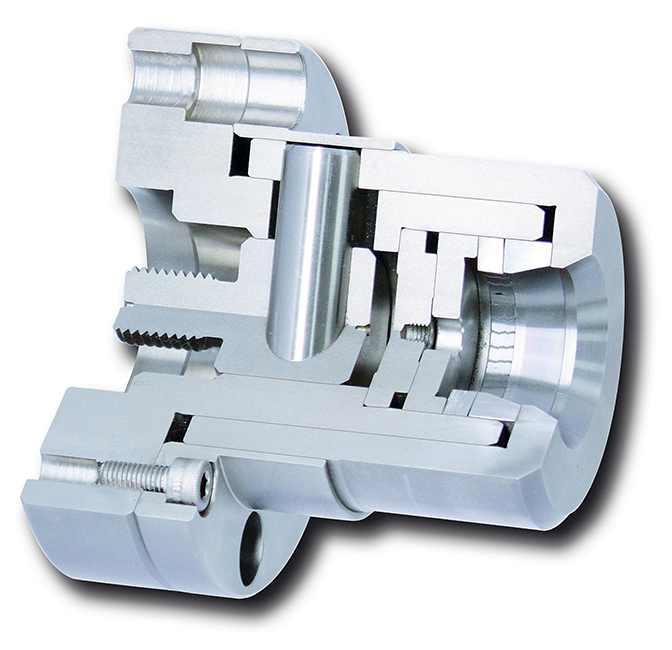

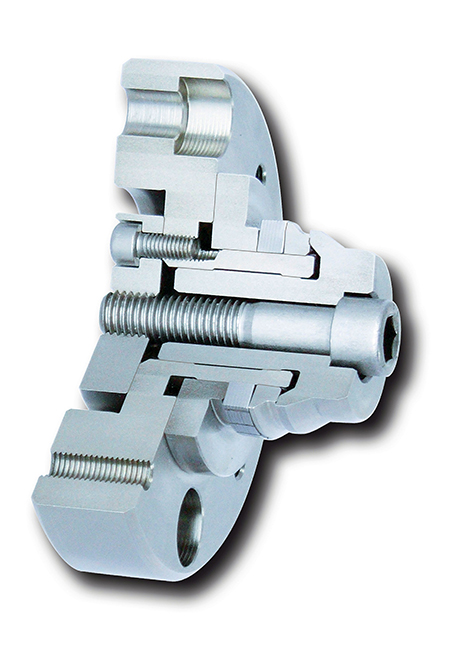

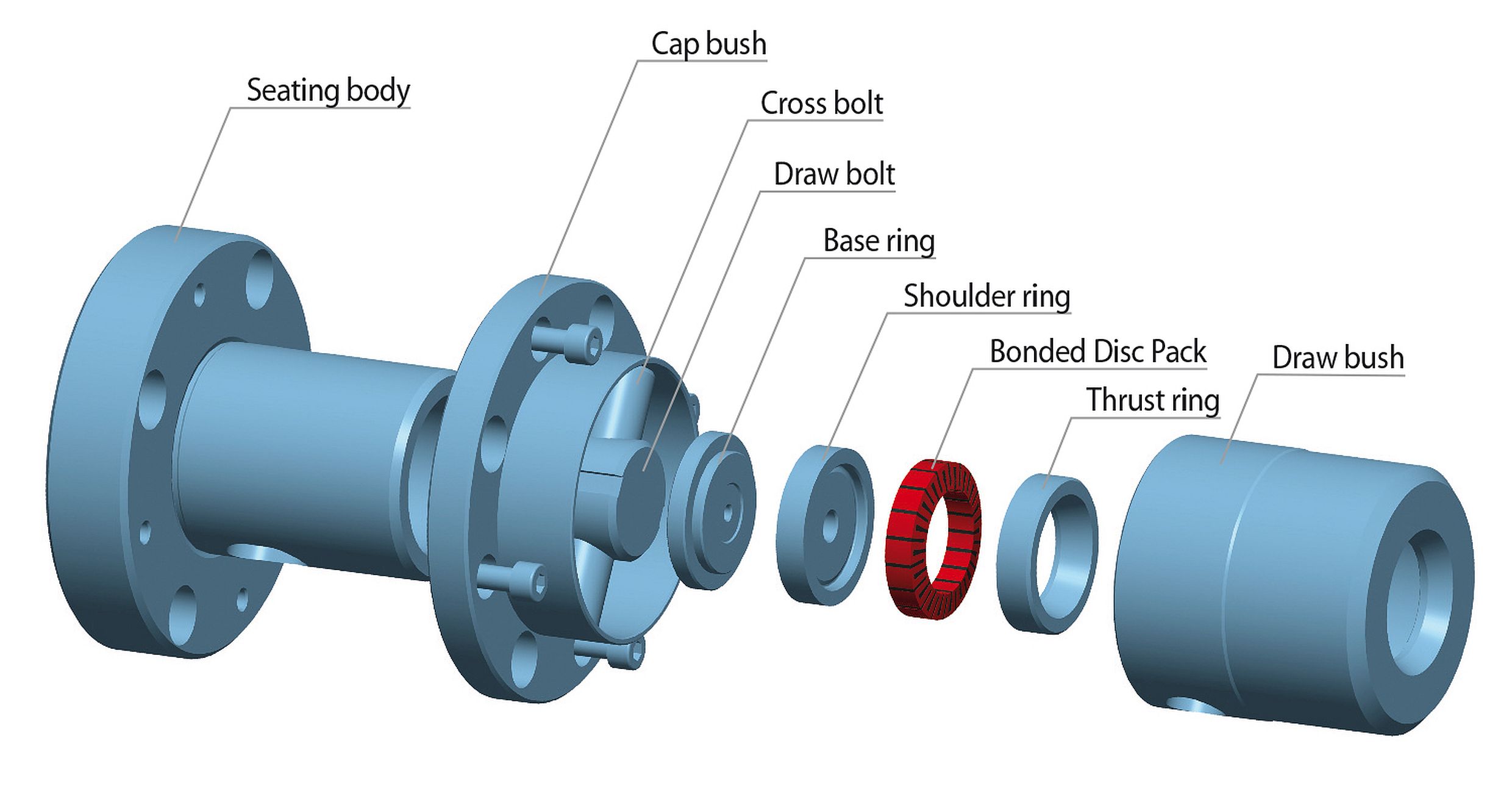

A RINGSPANN bonded disc pack flange chuck consists of a seating body, cover sleeve, cross and tension bolt, bottom and shoulder ring, bonded disc pack, thrust ring and tension sleeve. It is attached to the machine with the seating body and is actuated by the tension bolt, which is connected to the power clamping device of the machine.

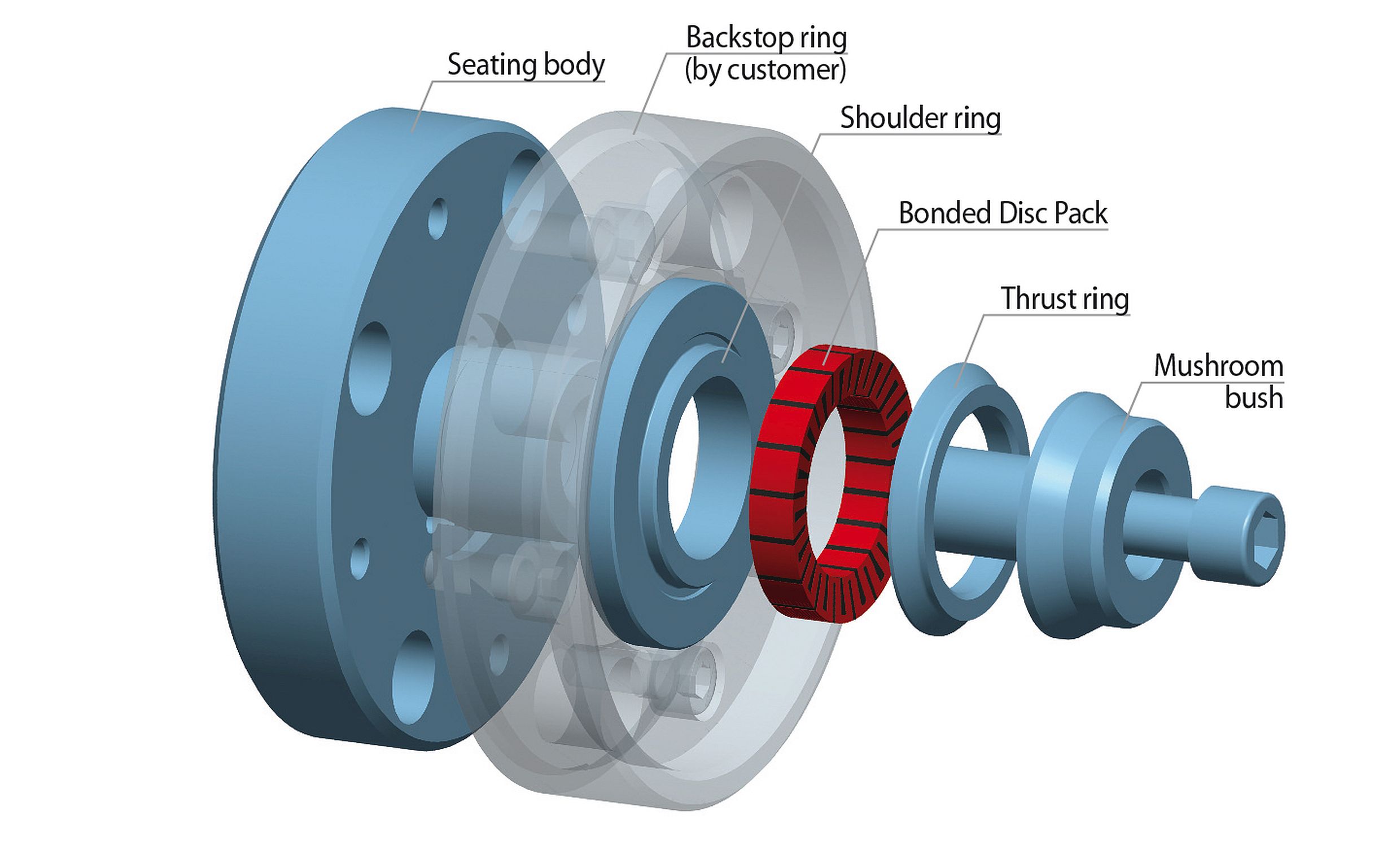

A RINGSPANN bonded disc pack flange mandrel consists of a seating body, shoulder ring, bonded disc pack, thrust ring and mushroom bush (for manual clamping optional: threaded plate). It is attached to the machine with the seating body and is actuated by the central screw of the mushroom bush, which is coupled to the power clamping device of the machine.

Depending on the torque to be transmitted, the flange chucks and mandrels can be fitted with bonded disc packs of different widths. The bonded disc pack sits under pre-stress in the support diameter of the seating body. By applying an axial actuating force, it straightens up, whereby the workpiece is centred, pressed flat against a shoulder ring and aligned. By tilting the bonded disc pack, the axial actuating force is translated into a radial clamping force that is up to 10 times greater.